| Here pictures of the intake before I got it. I didn't get the throttle body in the sale. |

|

|

|

|

| The following pictures are of the intake and fuel rails after a thorough cleaning and

polishing. I also painted the groves in the plenum black and the grooves in the fuel

rails black. I also needed to create a fuel crossover tube since the original one was gone.

I made that out of 3/8 fuel line and AN fittings. I also painted all the fuel rail fittings

black. |

|

|

|

|

|

|

|

|

|

|

|

|

| Here are pictures of the factory Holley regulator. This was also damaged in the fire but,

that didn't concern me because I already had an Aeromotive adjustable regulator. The

only issue is I needed to plug the hole in the fuel rail where the regulator mounts and use

the rear rail fittings for the fuel lines. I cut up the old regulator to get the nipple

that goes into the fuel rail. I then welded this nipple to a solid piece of steel. This

was then bolted to the fuel rail. |

|

|

|

|

|

|

|

|

| First I needed to remove the TPI intake manifold from the engine. |

|

|

|

|

|

|

| I then mounted the Aeromotive regulator to the fuel rail. Originally I had it install on

passenger side but moved it to the driver's side for clearance reasons. |

|

|

|

|

| The next step was to install the lower portion of the intake. |

|

|

|

|

|

|

| Next was the various plumbing. I hooked up the heater lines and then installed the fuel

rails and injectors. |

|

|

|

|

|

|

|

|

|

|

| Next I installed the various vacuum fittings and the intake air temperature sensor into

the upper plenum. |

|

|

|

|

|

|

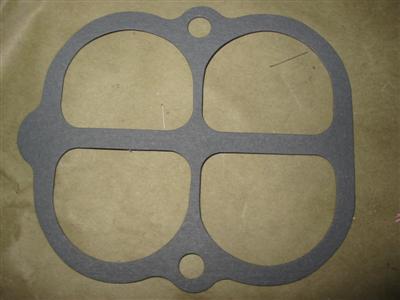

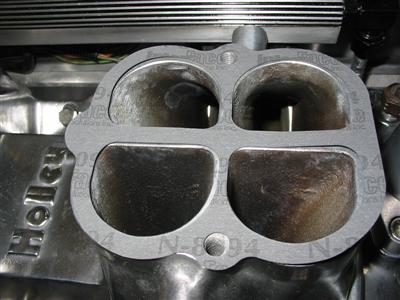

| The next step was to modify the gasket used between the upper and lower plenum. The

gasket was originally for a tunnel ram. To make the gasket work I needed to remove the

center section in the gasket. |

|

|

|

|

|

|

| Here is the whole mainshaft now loaded up with the 3rd and 4th gear assemblies and with

the input shaft test fitted. |

|

|

|

|

| The bottom of the throttle body required a bit of clearancing to clear the water neck. Lastly,

I then installed the throttle body, intake tract with MAF sensor, Lokar throttle bracket,

and wiring. |

|

|

|

|

|

|

|

|

|

|

|

|